News

-

Super stainless steel

Super stainless steel and nickel-based alloy are a kind of special stainless steel. Firstly, they are different from ordinary stainless steel in chemical composition. They refer to a kind of high-alloy stainless steel with high nickel, h...Views -

Cobalt alloy casing

Cobalt (Co)-based alloys (Stellite) are widely used in wear environments due to their good corrosion resistance, wear resistance and wear resistance. It is not only wear-resistant, but also anti-corrosive, and can withstand high temperat...Views -

Invar36 casting

Invar 36, also known within the industry as Nilo 36, is a nickel-iron superalloy known for its low coefficient of thermal expansion.Containing 36% nickel, it maintains nearly constant dimensions as well as good strength and hardness over...Views -

Superalloy

Superalloys or high-performance alloys are alloys that exhibit excellent mechanical strength and creep resistance, good surface stability, and corrosion and oxidation resistance at high temperatures. They usually have an austenitic face-...Views -

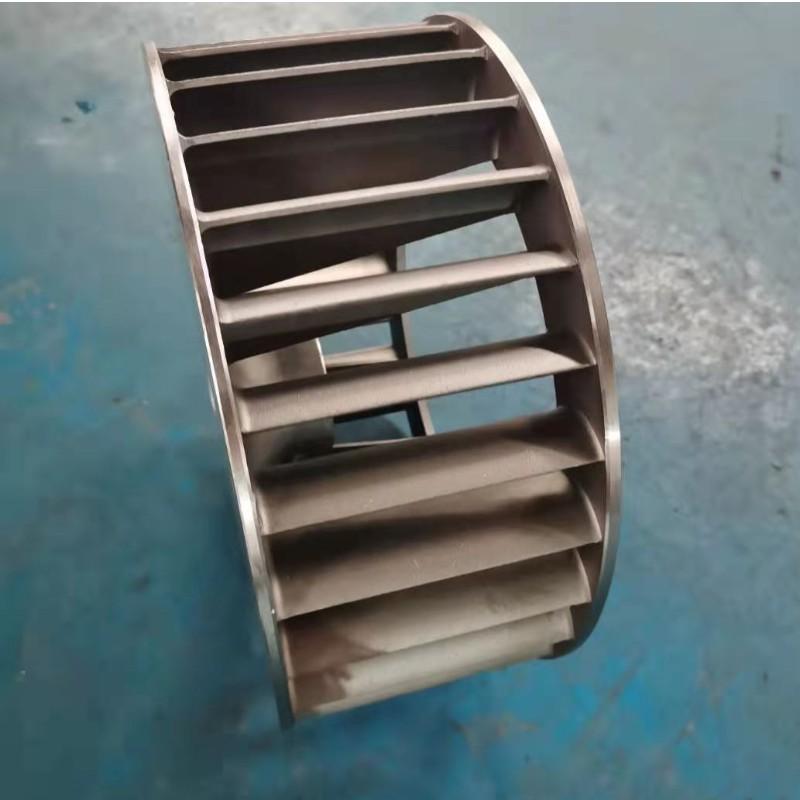

UNS N07713/alloy 713C impeller

At the beginning of the 21st century, the economy and aviation market suffered severe crises, leading to the development of more efficient products by aircraft and engine manufacturers. The new generation of aircraft has improved aerodyn...Views -

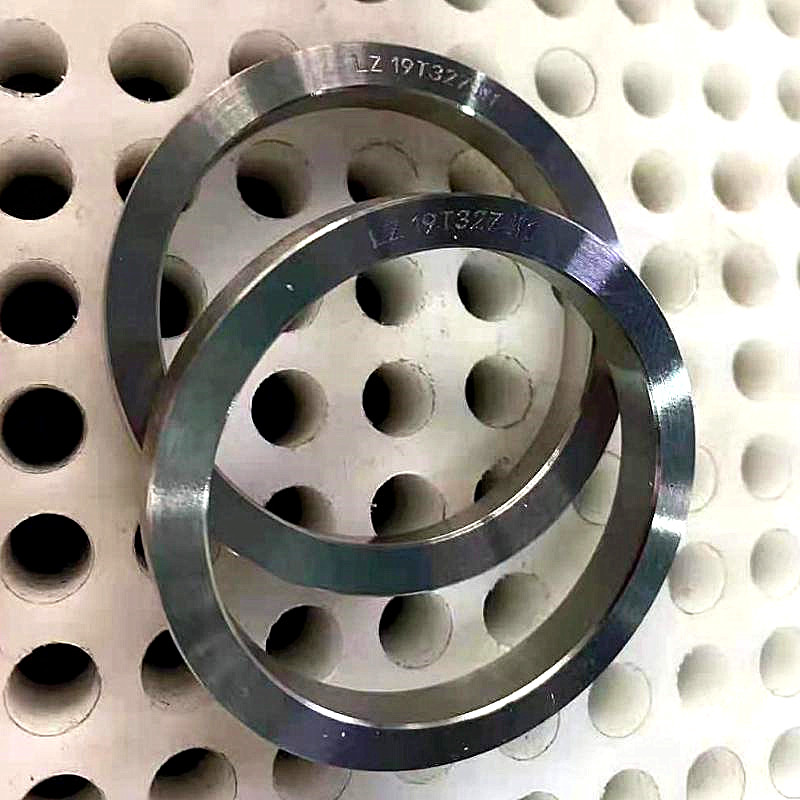

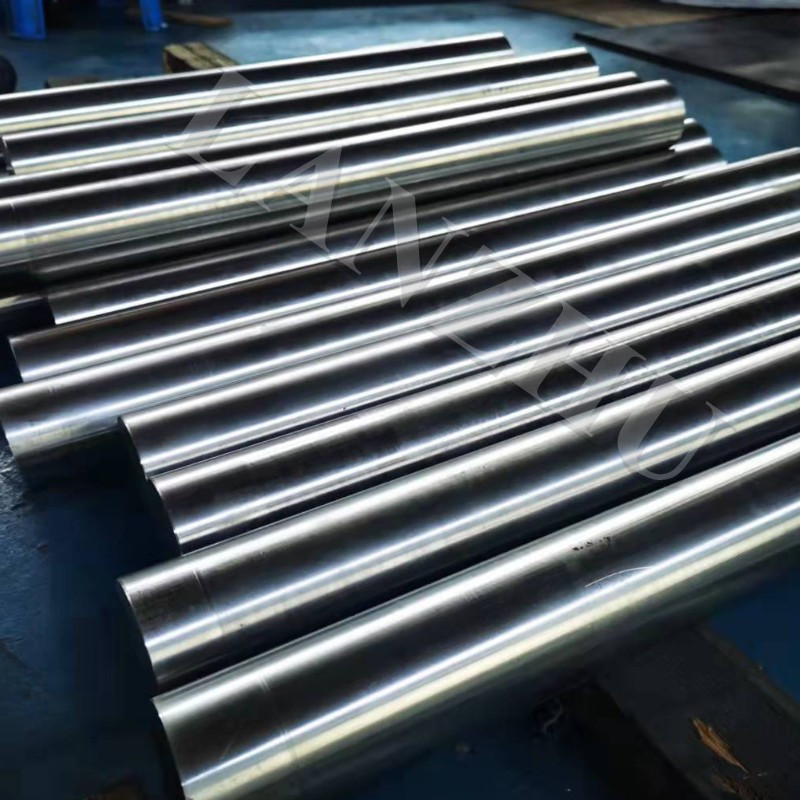

Inconel®X-750 Bar

Material characteristicsIt has good corrosion resistance and oxidation resistance below 980℃, high strength below 800℃, good relaxation resistance below 540℃, and good formability and welding performance. It has good performance in lo...Views -

Metal 3D printing as a disruptive technology for superalloys (2)

Materials and manufacturing design for metal 3D PrintingWe envisage carefully prescribed computer-aided design models along with model-based designer alloys and optimised--and indeed spatially varying--3D printing strategies to achieve h...Views -

Metal 3D printing as a disruptive technology for superalloys

3D printing can allow for the efficient manufacturing of elaborate structures difficult to realise conventionally without waste, such as the hollow geometries of nickel-based superalloy aeronautic components. To fully exploit this method...Views -

Invar36 alloy powder

Alloy 36 is a special low-expansion iron-nickel alloy with an ultra-low expansion coefficient. Cold deformation can reduce the coefficient of thermal expansion and stabilize the coefficient of thermal expansion within a specific temperat...Views -

1j79 alloy powder

1j79 is a commonly used iron-nickel alloy (soft magnetic alloy), which can also be called Bromo alloy. It mainly achieves sufficient magnetic permeability and magnetic saturation induction through a reasonable combination of nickel and i...Views -

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (6)

1.Conclusions In this work, we performed a detailed analysis of the precipitation kinetics of an AM IN625 alloy fabricated using L-PBF during heat treatment at 700 ◦C. Whereas previously reported residual stress heat treatments at ...Views -

Solid-State Transformation of an Additive Manufactured Inconel®625 Alloy at 700 ◦C (5)

Figure 7b shows the evolution of the mean thickness (minor dimension) and diameter (major dimension) of the δ phase precipitates at 700 ◦C as a function of time. The thickness and diameter demonstrate a similar trend, with an initial r...Views