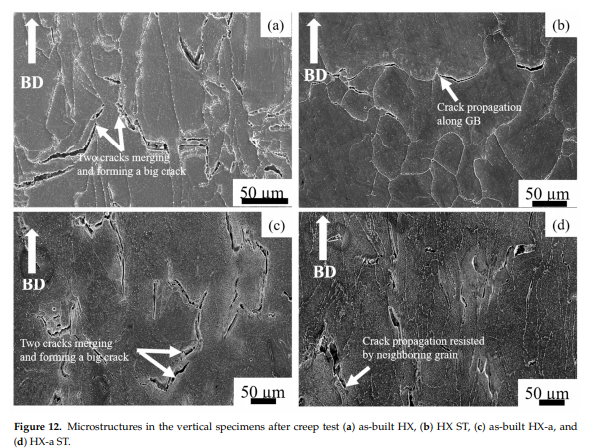

Figure 12 shows the microstructures of the vertical specimens along the loading direction after the creep test. The HX as-built specimen had large cracks (Figure 12a) along the horizontal grain boundary; these cracks merged and formed significant cracks, resulting in a brittle fracture. We also observed cracks along the grain boundaries in the HX-a asbuilt specimen (Figure 12c). After solution heat treatment, the HX ST specimen exhibited equiaxed grain morphology, resulting in brittle fracturing of the grain boundary after the creep test (Figure 12b). However, the HX-a ST specimen showed a transgranular fracture (Figure 12d), resulting in a ductile fracture. In addition, in HX-a ST, specimen cracks were aligned parallel to the loading axis, making it difficult for the cracks to propagate normal to the stress axis and resulting in a ductile fracture.

1. Discussion

1. Effect of Segregation on the Hot Cracking Formation

Hastelloy-X is a solid-solution-strengthened Ni-based alloy, and it can exhibit a wide range of melting and solidification temperatures due to its high alloy content. During the SLM process, the base metal adjacent to the fusion zone experiences a range of peak temperatures between the alloy’s liquidus and solidus temperatures. Therefore, this region’s microstructure undergoes partial melting and is described as the partially melted zone (PMZ) region of the HAZ [25]. Liquation cracking occurs at the grain boundaries in the heat-affected zones of welds, also known as HAZ fissuring. During liquation cracking, when the heat melts, low-melting-point phases form on the grain boundaries and at the interdendritic area in the heat-affected zone from a weld run. A liquid film forms on these grain boundaries and interdendritic regions and is pulled apart by the tensile thermal stresses as the weld solidifies. Phases that are likely to be liquated in Ni-based superalloys include MC carbide, M6C carbides, Laves phase, and σ-phase [12,26]. The same phenomena were observed in the as-built HX sample (Figure 3a); that is, the segregation of elements such as Si, W, and C brought about the formation of SiC- and W6C-type carbides at the grain boundary and interdendritic areas during the solidification process, eventually causing the formation of a crack in the HX specimens (Figures 1a and 3a) [8,17]. The HXa specimen showed more cracks (Figure 1b) than the HX specimen because its elements were segregated similar to that for additional yttrium (Y) and higher-content Si (Table 1), which resulted in the formation of carbide, mainly MC (M stands for Si, Y) and M6C (M stands for W) and caused more cracks to appear (Figure 3b) [26,27]. The solid solubility of Y in the Ni matrix is low and affects crack formation because Y is rejected from the core dendrite to interdendritic regions, causing segregation problems.