3.1.2. ST Specimens

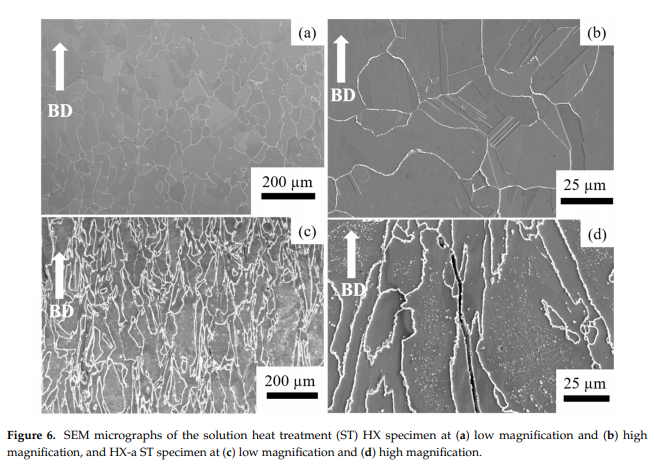

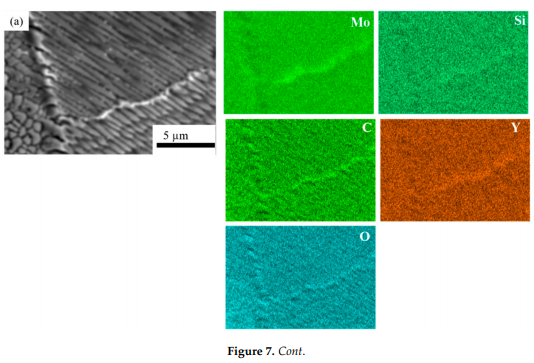

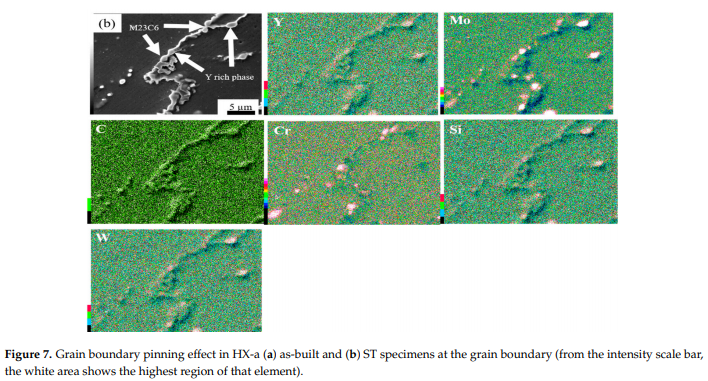

Figure 6 shows SEM micrographs after ST heat treatment. The boundaries of molten pools and dendritic structures disappeared. The HX ST specimen presented equiaxed grain morphology at lower magnification (Figure 6a). That specimen also showed a lot of twins at higher magnifications (Figure 6b). For the HX-a specimen, the ST specimen’s grain morphology was similar to that of the as-built sample (Figure 6c). Two main differences were observed between the HX specimen and the HX-a specimen after ST treatment: in the latter, the grain boundary became thicker with carbide, and those fine carbides formed inside the grain (Figure 6d). In the former, on the other hand, no carbides were observed inside the grain, and the grain boundary was thinner than that of the HX-a ST specimen (Figure 6b). We carried out SEM analysis of the HX-a as-built specimen at the grain boundary; the results are presented in Figure 7a. M6C, SiC, and YC were formed at the grain boundary. These carbides at the grain boundary must have pinned the boundary during the solution heat treatment. We carried out FE-SEM analysis at the grain boundary in the HX-a ST specimen. Figure 7b shows the FE-SEM micrograph of the HX-a ST specimen. MC (Si, Y), (Mo, W)6C, and Cr23C6 carbides were formed at the grain boundary. These mainly caused the grain boundary pinning effect to eventually maintain a columnar grain morphology.

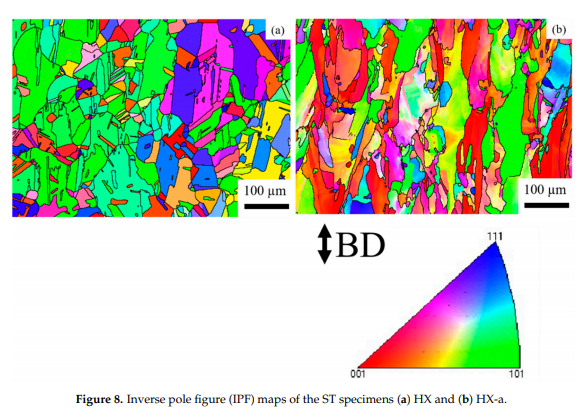

Figure 8 shows the IPFs of the HX and HX-a specimens at the ST condition. After the solution heat treatment, the HX specimen showed equiaxed grains and the orientation was random (Figure 8a). Most of the grains have a direction along (Figure 8a). However, the HX-a specimen appeared to be similar to the HX-a as-built specimen (Figure 5b); that is, it had a columnar grain morphology and half of the grains remained along the <100>direction (Figur 8b).

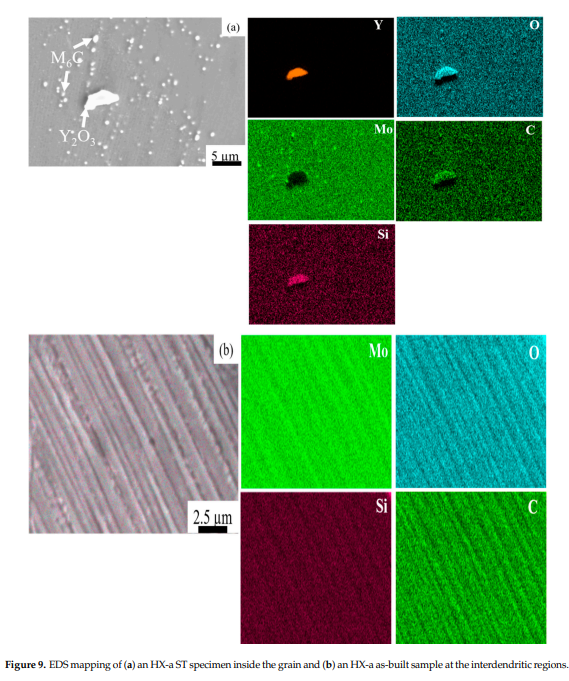

Figure 9a shows EDS mapping of the HX-a ST specimen, which indicates Mo-rich carbides inside the grain. There was also the formation of an oxide of Y and Si-containing C inside the grain (see Figure 9a). In order to find the reason for the accumulation of M6C carbides along the interdendritic regions after the solution heat treatment, we performed EDS mapping at the interdendritic areas of the HX-a as-built specimen (Figure 9b); at the interdendritic regions, Mo, Si, C, and O were segregated. Materials 2021, 14, x FOR PEER REVIEW 8 of 16 Figure 9a shows EDS mapping of the HX-a ST specimen, which indicates Mo-rich carbides inside the grain. There was also the formation of an oxide of Y and Si-containing C inside the grain (see Figure 9a). In order to find the reason for the accumulation of M6C carbides along the interdendritic regions after the solution heat treatment, we performed EDS mapping at the interdendritic areas of the HX-a as-built specimen (Figure 9b); at the interdendritic regions, Mo, Si, C, and O were segregated.

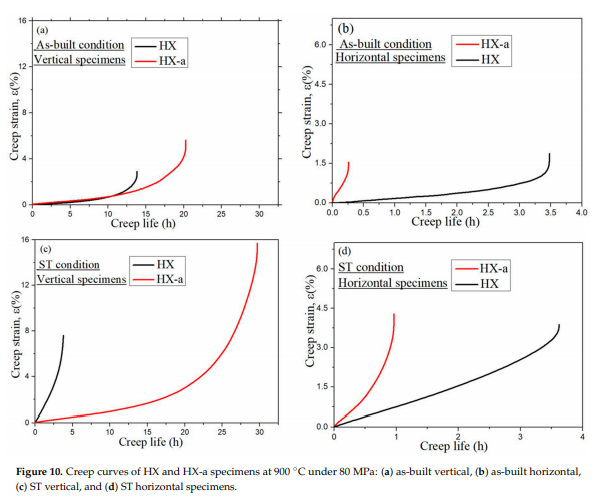

We conducted a creep test along the building direction (vertical specimen) and normal to building directions (horizontal specimen); the creep curves are presented in Figure 10. In the as-built condition, the vertical HX specimen exhibited a creep life of 13.8 h while the HXa specimen exhibited a creep life 1.46 times higher, 20.2 h (Figure 10a). Moreover, the HX-a revealed a higher creep-rupture elongation (5.7%) than the HX (2.8%). The HX as-built horizontal specimen exhibited longer creep life (3.4 h) than the HX-a horizontal specimen (0.26 h), but the rupture strain was almost the same in both specimens (Figure 10b). Figure 10c shows the creep properties of ST vertical specimens. The HX specimen exhibited a creep life of 3.7 h, while the HX-a specimen showed a creep life eight times higher, 29.6 h. The HX-a showed a higher creep-rupture elongation (15.6%), almost double that of the HX (7.5%). The HX ST horizontal specimen exhibited longer creep life (3.6 h) than the HX-a horizontal specimen (0.26 h), but the creep-rupture elongation was nearly the same in both specimens (Figure 10d). Materials 2021, 14, x FOR PEER REVIEW 9 of 16 We conducted a creep test along the building direction (vertical specimen) and normal to building directions (horizontal specimen); the creep curves are presented in Figure 10. In the as-built condition, the vertical HX specimen exhibited a creep life of 13.8 h while the HX-a specimen exhibited a creep life 1.46 times higher, 20.2 h (Figure 10a). Moreover, the HX-a revealed a higher creep-rupture elongation (5.7%) than the HX (2.8%). The HX as-built horizontal specimen exhibited longer creep life (3.4 h) than the HX-a horizontal specimen (0.26 h), but the rupture strain was almost the same in both specimens (Figure 10b). Figure 10c shows the creep properties of ST vertical specimens. The HX specimen exhibited a creep life (3.6 h) than the HX-a horizontal specimen (0.26 h), but the creep-rupture elongation was nearly the same in both specimens (Figure 10d).

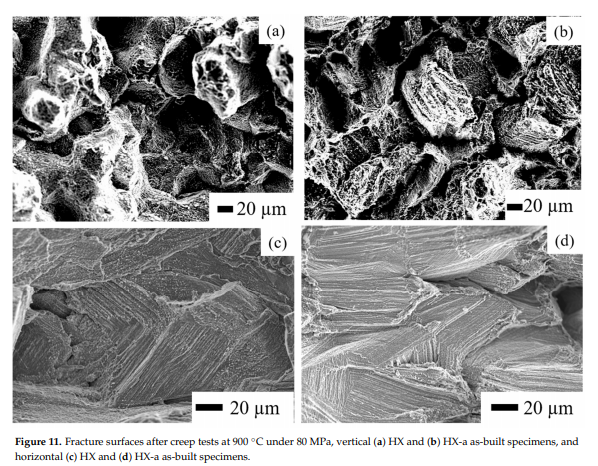

Figure 11 shows the creep-rupture surfaces. It is evident from Figure 11a,b that the HX and HX-a as-built vertical specimens exhibited elongated grains, which eventually show necking and induce fracturing. By contrast, a rather cleavage-like surface can be observed on the as-built HX and HX-a horizontal specimens (Figure 11c,d, respectively). Obviously, the cracks present perpendicular to the stress axis resulted in the cleavage-like surface along the dendritic structure, indicating brittle behavior and lower ductility.