4.2. Heat Treatment and Anisotropy Effects on Creep Properties

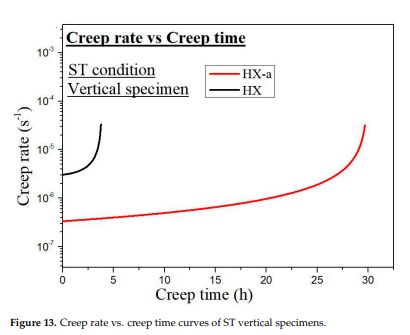

First, we considered the grain morphology effect on creep properties. In the as-built condition, both HX and HX-a specimens exhibited columnar grain formation (Figure 5). Columnar grain formation is a natural phenomenon in additive manufactured materials. This has been proven by many researchers in different alloys [28,29]. The columnar grains are attributed mainly to epitaxial grain growth, a consequence of layer-by-layer formation with rapid heating and cooling during the SLM process [30]. It is well known that materials that have a columnar grain morphology exhibit better creep properties [31]. Although the HX-a as-built specimen had many cracks, it showed better creep properties than the HX specimen. The HX-a vertical specimen’s creep properties showed 1.46 times longer creep life than the HX vertical specimen in the as-built condition (Figure 10a). In addition, yttrium addition in the HX-a specimen formed oxides of Y and Si (Figure 4) and prolonged creep life compared to the HX specimen. The creep properties of the horizontal as-built sample are depicted in Figure 10b. In the horizontal specimens, the HX-a specimen showed an inferior creep life compared to the HX specimen. This is due to the presence of cracks perpendicular to the stress axis (Figure 1b). As a result, the HX specimen having fewer cracks (Figure 1a) showed a longer creep life than the HX-a specimen. However, due to cracks and columnar grain morphology in the as-built condition, anisotropic creep properties prevailed in both HX and HX-a specimens. The solution treatment changed the microstructures of the HX and HX-a specimens. After the solution heat treatment, the HX specimen showed an equiaxed grain morphology and the orientation became random (Figure 8a). On the other hand, the HX-a specimen maintained a columnar morphology (Figure 8b). The SEM analysis of the HX-a as-built sample at the grain boundary revealed the formation of carbides at the grain boundary, indicating that the grain boundary pinning effect maintained the columnar grain morphology (Figure 7a). FE-SEM analysis was carried out at the grain boundary in the HX-a ST specimen to find phases at the boundary. MC (Si, Y), (Mo, W)6C, and Cr23C6 carbides formed at the grain boundary (Figure 7b). The grain boundary pinning by carbides eventually maintains the columnar grain morphology. Another vital difference between the HX and HX-a ST specimens is the formation of M6C carbides inside the HX-a specimen’s grains (Figure 9a). Yttrium promotes a high density of fine Mo-rich carbides and larger oxide inside the grain (Figure 9a). Creep life along the vertical direction of the HX-a ST specimen (29.6 h) was eight times better than that of the HX ST specimen, and creeprupture elongation became almost double that of the HX ST specimen (Figure 10c). The HX-a ST specimen’s grain morphology was similar to those of the directionally solidified (DS) Ni-based superalloys [29]. Grain boundaries normal to the stress axis are usually the crack initiation sites in conventionally cast superalloys. Therefore, the columnar grain morphology improves the creep life. Thus, the HX-a ST vertical specimen exhibited better creep properties than the HX ST vertical specimen. On the other hand, the HX ST creep test resulted in low creep life and ductility because of the equiaxed grain morphology in the HX ST specimen. There are two additional reasons behind the creep life improvement in the HX-a ST vertical specimen. First, the formation of M6C carbides inside the grains in the HXa specimen (Figure 9a) also affects creep life improvement in the HX-a ST vertical specimen. Second, the Y and Si oxides are stable even at higher temperatures; they also improve creep resistance by hindering dislocation motion; moreover, grain boundary carbides control grain boundary sliding, resulting in the lower creep rate in the HX-a specimen (Figure 13).

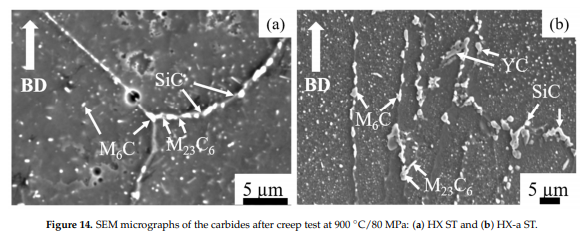

Additionally, the formation of continuous carbides at the grain boundary (Figure 14a) results in low ductility; since carbides are brittle phases once the crack nucleates, it propagates rapidly, reducing elongation (Figure 10c). However, from the comparison between Figure 6d and Figure 14b, the discrete carbide increased during the creep test in HX-a ST and improved creep ductility because these carbides (Figure 14b) resist grain boundary sliding and the resultant crack formation. A creep test was also conducted on horizontal solution heat-treated specimens. In the HX-a specimen (Figure 1b), these cracks align perpendicular to the stress axis, and the stress concentration at the crack tip increases. The easy crack propagation results in low creep properties. The HX horizontal specimen showed better creep life than the HX-a horizontal specimen (Figure 10d) since the former had fewer cracks (Figure 1a).