Products

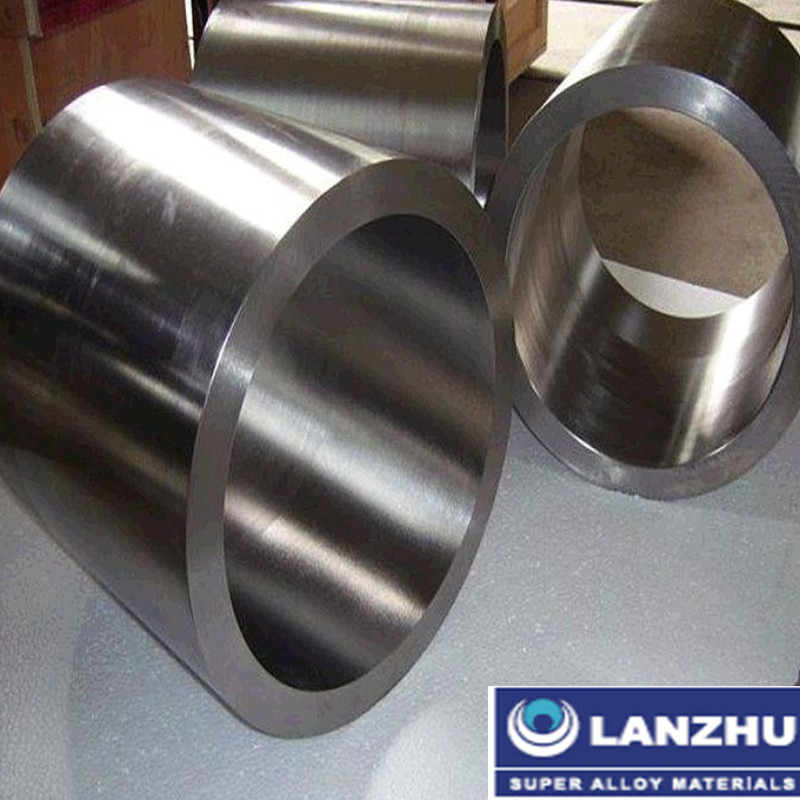

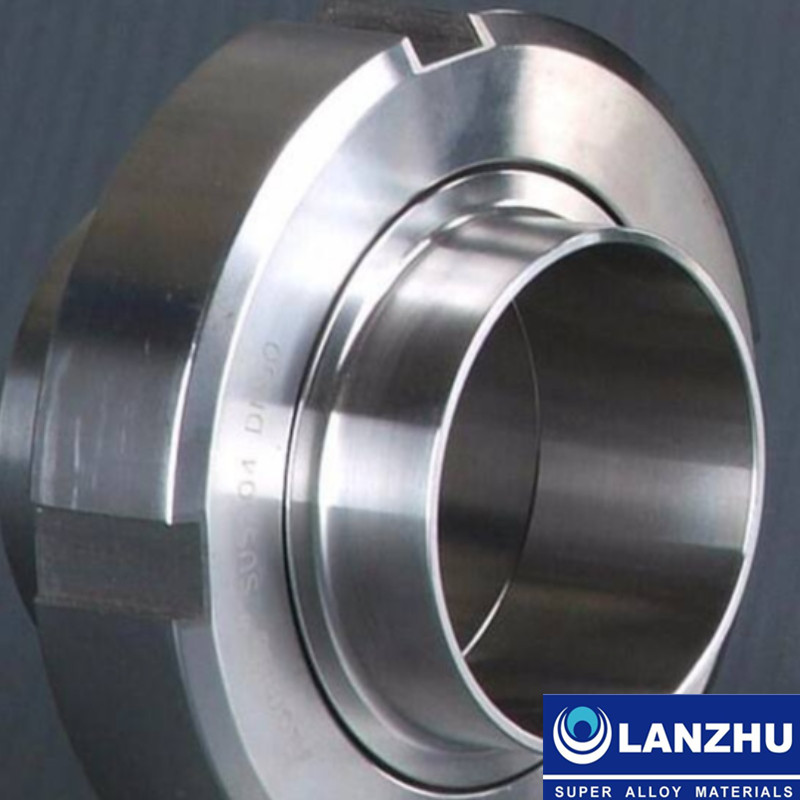

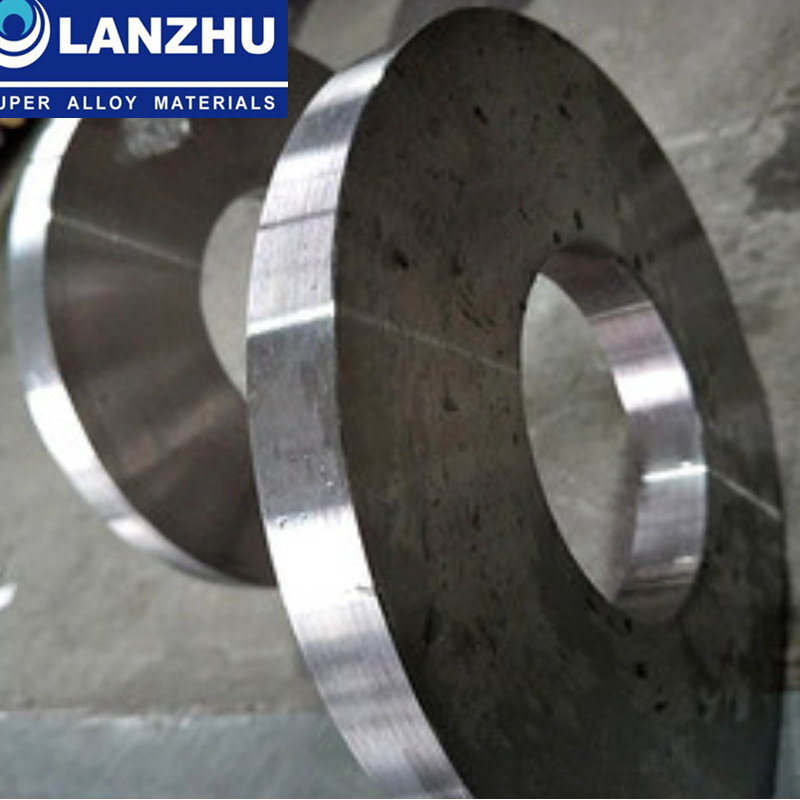

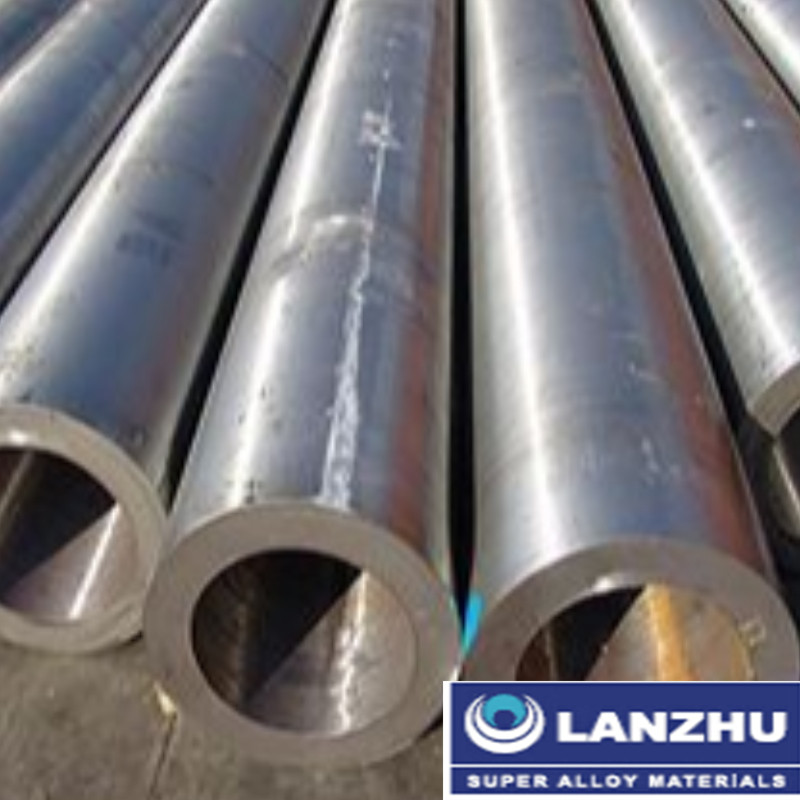

Inconel®625 Sleeve, ring, disc(alloy625,UNS N06625,W.Nr.2.4856,NiCr22Mo9Nb,NA21)

Five Advantages Of Products

- Widely used in engine structural parts

- Resistant to salt spray corrosion and oxidation

- Executive Standard:ASTM, AMS, DIN,ISO,API6A

- Custom forged products

- Fast product production cycle

Product Details

Alloy625 Material characteristics

It has excellent corrosion resistance and oxidation resistance,has good tensile properties and fatigue properties from low temperature to 1796℉,and is resistant to stress corrosion in a salt spray atmosphere. Therefore,it can be widely used in the manufacture of aero engine parts,aerospace structural parts and chemical equipment,and occasions that are exposed to seawater and subject to high mechanical stress.

Alloy625 Application field

.Components of chloride-containing organic chemical processes,especially where acid chloride catalysts are used

.Manufacture of digesters and bleaching tanks in the pulp and paper industry

.Absorption tower,reheater,flue gas inlet baffle,fan (wet),agitator,deflector,and flue in the flue gas desulfurization system

.Manufacture of equipment and components for use in acid gas environments

.Acetic acid and acetic anhydride reaction generator

.Sulfuric acid condenser

We produce ALLOY718 alloy materials to meet the special standard requirements provided by customers. We produce forgings and customize products according to customer requirements,including shaping die forging, product secondary processing and special process requirements,ranging from 5mm to 3000mm in diameter. Our mature material control and automated process control ensure the stable quality and dimensional accuracy of the product.

Product specification range

Bar:Diameter 8mm-350mm ,Length 500mm-5000mm

Profile:Diameter 8mm-280mm ,Length 500mm-5000mm

Casing:Diameter 200mm-φ1500 ,Length 100-800mm

Ring:Diameter 150mm- 1500 ,Length 100-2000mm

Disk:Diameter 200mm-1500 ,Length 100-800mm

Die forging:Single weight is greater than 8kg

What is the delivery time?

Answer:Usually 15-50 days,email communication according to the requirements.

Where do you usually ship from?

Answer:Usually sent from Shanghai.China

Accepted payment methods?

Answer:We accept payment by T/T,L/C

Shanghai LANZHU super alloy Material Co., Ltd.

Contact Person: Una

Department: Market Department

Post: Product manager

Telephone: +86 13817160919

Landline: +86 021-59150215

Company Address: No. 2800 Caoxin Road, Xuhang Town, Jiading District, Shanghai

Factory Address: No. 2800 Caoxin Road, Xuhang Town, Jiading District, Shanghai

Website: www.super-alloy.com.cn

Previous: Inconel®718 Tubing hanger ,Sleev...

-

Inconel®690 seamless tube,pipe,ring,Sleeve

-

Incoloy ®800H seamlness tube,pipe,ring,Sleeve

-

Monel®400 seamlness tube,pipe,ring,Sleeve

-

Hastelloy®X seamlness tube,pipe,ring,Sleeve

-

Hastelloy®C-276 seamlness tube,pipe,ring,Sleeve

-

Incoloy®825 seamlness tube,pipe,ring,Sleeve

-

Inconel®718 tube,pipe,ring,Sleeve

-

Inconel®625 Seamless tube,pipe,ring,Sleeve(UNS N06625,W....