This is a quantity, which is frequently used in the literature. As can be seen in Fig. 15, the true ath(-T) data show the sharp peak, which we exploit for the determination of c-solvus in the present work, while & this feature is largely smoothed out by averaging in the case of athMEANðTÞ. Figure 15 presents digitalized data from different sources [58, 59, 63-71]. All authors performed their experiments using heating rates between 2 K/min and 5 K/min. Data for Ni (full circles) were reproduced from the work of Sung et al. [63], who have created a regression line from various previous data [64–67] and the data for Ni3Ti (empty circles) were reproduced from the work of Karunaratne et al. [68] (who refer to previous publications [65, 69, 70]). It is interesting to compare these data with dilatometric results for the c-phase (empty squares) and for the c-phase data (full squares), & which were isolated from CMSX-4 by Siebo¨rger et al. [58]. Their data represent true thermal expansion; however, the isolated phases cannot adjust their chemical composition to c/c-equilibrium. Thus, no & peak in thermal expansion like that observed in our work appears. Morrow et al. [71] investigated the influence of Mo additions to a Ni-base superalloy with c/c-microstructure and showed that increasing & Mo levels and Al-levels result in a small decrease in thermal expansion coefficients. In Fig. 15, we reproduce their data for a Ni-based alloy with 3.5% Mo (empty triangles). Finally, we add the recently published CMSX-4 data set from Quested et al. [59] (thick dashed line). The comparison reveals that while there is some scatter, all data are reasonably close when we compare them to our mean thermal expansion coefficient. Note that our mean thermal expansion data and the Quested et al. [59] are in excellent agreement. Our true expansion data, however, deviate significantly toward higher values and show the sharp peak, which allows to determine the c-solvus & temperature.

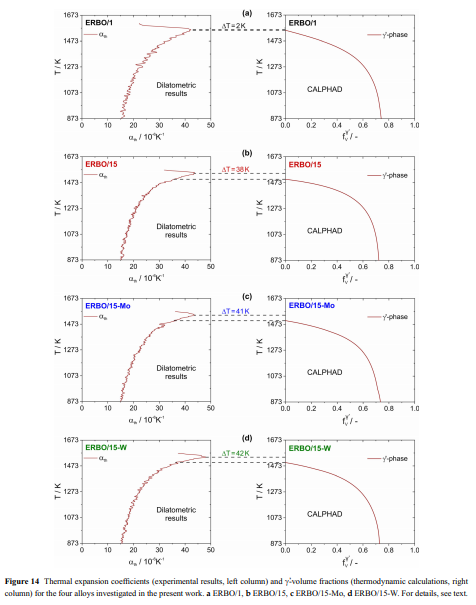

Our true thermal expansion data show a pronounced sharp peak (highlighted by an arrow) at high temperatures where the thermal expansion coefficient drops by almost 50%. The data presented in Figs. 7, 8, 9, 13 and 14 clearly suggest that this drop is associated with the c-solvus temperature. For & ERBO/1 (CMSX-4 type), the drop occurs at a temperature, which is very close to the c-solvus tem- & perature as predicted by ThermoCalc. In case of the three ERBO/15-type alloys, the thermal expansion drop occurs at temperatures, which are 40 K above the predicted c-solvus temperatures. There is a better & agreement between measured (dilatometry) and calculated (ThermoCalc) c’-solvus temperatures for ERBO/1 than for ERBO/15 and its variants (Tables 7 and 8, Figs. 10, 11). This is in line with the finding that the experimentally determined alloy compositions for ERBO/1 (3D-APT, [36], standard material of CMSX-4 type) are in better agreement with the corresponding ThermoCalc predictions than in the case of the experimental ERBO/15 alloys (experimental data: TEM-EDX, [32]). The discrepancy between the c-solvus temperatures determined experimentally & and the ThermoCalc predictions for the ERBO/15 alloys as well as the differences in phase compositions measured in TEM and predicted by ThermoCalc suggest that the ThermoCalc data base needs to be optimized for the new compositional range. The experimental results and the ThermoCalc predictions both suggest that reducing Mo or W levels has no significant effects on the c-solvus temperatures.

The focus of the present work was on determining c-solvus temperatures using true thermal expansion & measurements. In addition, we report elastic coefficients for four Ni-base single-crystal superalloys, which are useful for engineering design in stress temperature regimes where elasticity governs mechanical material behavior and for estimating thermal stresses associated with thermal fatigue loading. Our results are not directly applicable to assess creep properties. However, c-solvus tempera- & tures are a measure for the stability of c-particles, & which provide creep strength. Our results is therefore indirectly related to the creep behavior of singlecrystal Ni-base superalloys.