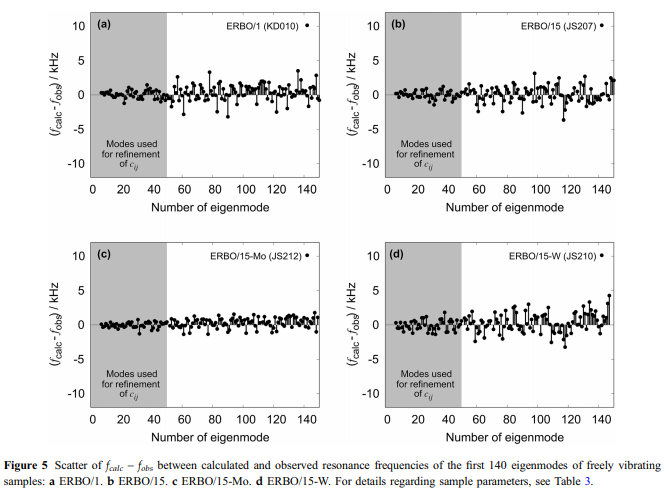

According to Demtro¨der et al. [41], the large-scale heterogeneities associated with the cast microstructure (dendrites and interdendritic regions) can influence the resonances with wave lengths of the order of the dendrite spacing. Following the procedure described by Demtro¨der et al. [41], elastic coefficients of all samples were refined on the basis of the 50 eigenmodes with the lowest frequencies (highlighted in gray in Fig. 5a–d) by a nonlinear leastsquares fit procedure. Taking a closer look at the differences between the experimentally observed resonance frequencies fobs and those calculated from the refined sample parameters fcalc at room temperature yields deviations between 0.33 and 0.6 kHz on average, which documents the good quality of the refinements. In Fig. 5, these differences are plotted as a function of the eigenmodes from the lowest to the highest resonance frequency. Demtro¨der et al. [41] have shown that this difference increases with decreasing sample size. Most importantly, good results are obtained when the specimen dimensions exceed the mean spacing between dendrites by at least a factor of 10. The authors also concluded that average deviations of less than 2 kHz are acceptable. As can be seen in Fig. 5, the average scatter observed in the present work does not exceed this value.

Dilatometry (DIL):High-precision dilatometry was used to monitor the temperature dependence of the coefficient of thermal expansion ath. The thermally induced strain eth, i.e. the relative change of sample length DL / L0 (L0: sample length at 293 K) with temperature, was measured between 100 and 1573 K using an inductive gauge dilatometer of type DIL402c from Netzsch as described in [41]. As can be seen in Fig. 4b (specimen clamped in between two ceramic rods, thermocouple close but not yet attached), the specimens used for the measurement of thermal expansion had the same geometry and crystallographic orientation as those taken for the assessment of the elastic stiffnesses, see Table 3. The dilatometer was calibrated with standard samples of the same lengths made of corundum. All experiments were performed in He-atmosphere at heating rates of 2 K/min. The coefficients of linear thermal expansion ath ¼ oeth=oT were determined as the first derivatives of the corresponding strain temperature curves. To this end, 40 (strain, temperature) data pairs within an interval of ± 1.5 K around each temperature Ti were approximated by a second-order polynomial from which athðTiÞ was calculated.

Thermodynamic calculations: In a multicomponent alloy, phase stabilities depend on alloy chemistry, temperature and pressure [43–45]. Today, the CALPHAD method (CALPHAD-short for: CALculation of PHAse Diagrams) originally developed by Kaufmann and Bernstein [45] can be used to calculate phase equilibria in multicomponent alloys [46, 47]. In the present work, ThermoCalc (a state-of-the-art CALPHAD implementation) in combination with database TCNi8, version 2019b [35]) was used to calculate thermodynamic equilibria with a focus on c-& solvus temperatures and the chemical compositions of the c- and the c- phases. Additionally, liquidus and & solidus temperatures as well as the c-volume frac- & tions were calculated as a function of the temperature for all four alloys. These calculations are based on a homogeneous chemical distribution of alloy elements in our SX. In reality, there is a dendritic solidification with dendritic (D) and interdendritic (ID) regions containing different chemical compositions. However, as has been shown in [36], the differences in average chemical compositions between D and ID regions are accounted for by an adjustment of volume fractions, the c-channels and the c-cuboids in & both regions had the same composition. Therefore, no effort was made to differentiate between D and ID regions, as far as the chemical compositions of the two phases are concerned.