The present work investigates how much large (ERBO/1 vs. ERBO/15) and small (three ERBO/15 variants) variations in alloy composition affect their thermoelastic properties. First objective: The comparison of two different alloys (large variation in alloy compositions) helps in the overall effort to move toward a superalloy single-crystal technology, where expensive and strategic alloy elements like Re, which are known to provide a high creep strength, are replaced by other elements without jeopardizing mechanical strength. Elastic and creep properties are both important in this respect. It has been proposed that this can be achieved by increasing the levels of Mo, Ti and W [34]. Further, elastic coefficients are needed in high-temperature engineering to design components, which need to withstand thermal fatigue loading. Therefore, an effort is made in the present work to measure elastic coefficients. Second objective: A detailed understanding of the role of individual alloy elements can only be obtained, when the effect of one particular element is studied. The comparison of the three ERBO/15 variants helps in this respect. Third objective: In particular, the potential of high-resolution dilatometry as a method for determining high c-solvus temperatures is & explored. For this purpose, we compare experimental results for c-solvus temperatures obtained by high- & temperature dilatometry with theoretical ThermoCalc calculations [35]. The quality of the ThermoCalc predications is assessed by comparing its predictions for the chemical compositions of the cand c-phases obtained using 3D atom probe tomog- & raphy (3D-ATP) [36] and transmission electron microscopy (TEM) [32]. To establish high-resolution measurements of thermal expansion as a method for determining c-solvus represents a significant pro- & gress in superalloy technology.

The results are discussed in light of previous work published in the literature. Areas, which require further research, are highlighted.

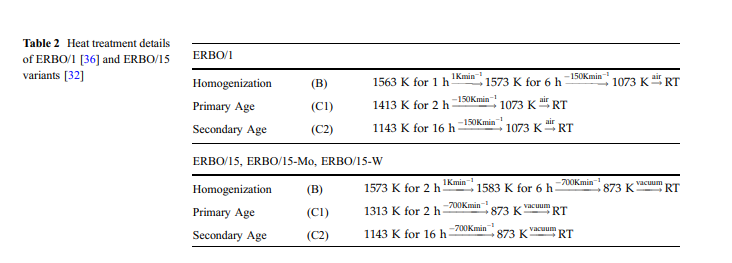

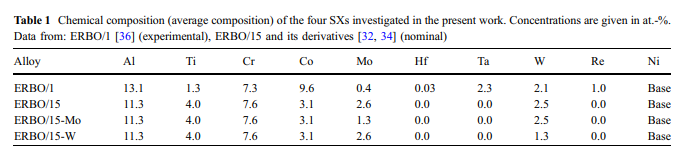

Materials, experiments and methods Materials: In the present work, four materials are investigated. Their nominal chemical compositions are listed in Table 1. ERBO/1 is a CMSX-4 type of alloy, details on processing, multiple step heat treatment and microstructure have been published elsewhere [32, 33, 36, 37]. ERBO/15 is a low-density Refree single-crystal Ni-base superalloy, which has been developed by Rettig et al. [34] using a numerical thermodynamic multi-criteria optimization method. In the present work, we compare ERBO/15 with two leaner ERBO/15 variants, which contain less W and less Mo (ERBO/15-W and ERBO/15-Mo). The heat treatment details of the four investigated alloys are presented in Table 2. While ERBO/1 was heat-treated by Doncasters Precision Castings in Bochum, the heat treatments of the ERBO/15 variants were performed in a custom-built vacuum heat treatment furnace from Carbolite Gero of type LHTM 100–200/16 1G. Detailed information about the heat treatment procedure is documented in [32] and [36]. Electron probe microanalysis (EPMA) was performed using an electron probe microanalyzer SX 50 for ERBO/1 and a field emission electron microprobe of type SXFiveFE for ERBO/15 and its two derivates, both from Cameca. It is well known that during solidification, alloy elements of SXs can vary in their tendencies to partition to dendritic and interdendritic regions. Figure 1 presents the distributions of the elements Al, Ti, Mo and W in the microstructure of ERBO/15 in the as-cast condition (upper row, Fig. 1a–d) and after the homogenization heat treatment (lower row, Fig. 1e–h). The lower row of Fig. 1 shows that the large-scale chemical heterogeneity, associated with the partitioning tendencies of the alloy elements during solidification, can be lowered during the homogenization step (Table 2); however, it does not completely vanish as can be seen for W in Fig. 1h. Scanning electron microscopy (SEM) investigations were performed using a Leo Gemini 1530 SEM from Carl Zeiss AG equipped with a field emission gun (FEG) operating at 12 kV and an inlens detector (working distance: 4.5mm, aperture: 30 mm).