ABSTRACT

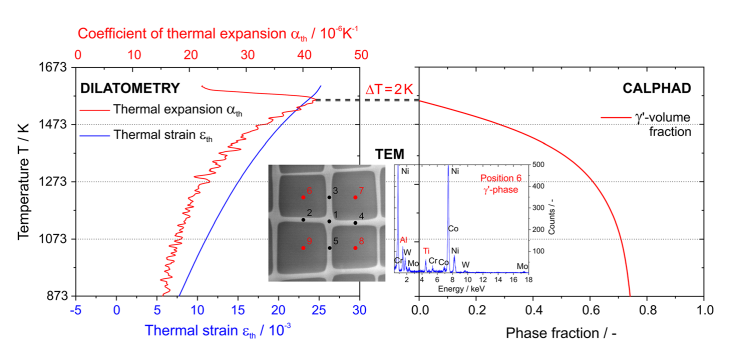

The present work shows that thermal expansion experiments can be used to measurethe c-solvus temperatures of four Ni-base single-crystal superalloys (SX), one with Re &and three Re-free variants. In the case of CMSX-4, experimental results are in good agreement with numerical thermodynamic results obtained using ThermoCalc. For

three experimental Re-free alloys, the experimental and calculated results are close.Transmission electron microscopy shows that the chemical compositions of the cand the c-phases can be reasonably well predicted. We also use resonant ultrasound &spectroscopy (RUS) to show how elastic coefficients depend on chemical composition and temperature. The results are discussed in the light of previous resultsreported in the literature. Areas in need of further work are highlighted.

GRAPHICAL ABSTRACT

Introduction

Ni-based single-crystal superalloys (SXs) are used tomanufacture turbine blades, which operate at temperatures above 1000 C. They have to withstand aload spectrum, which includes creep, thermal fatigue and hot corrosion. Creep strength, the resistance against a slow but continuous accumulation of strain,is of utmost importance. It is well known that SXs rely for their strength on a microstructure, which consists of sub-micrometer cuboidal c-particles &(crystal structure: ordered L12-phase; volume fraction: 70 vol.%) which are separated by thin c-channels (crystal structure: fcc; volume fraction: close to 30 vol.%), e.g., [1–4]. The crystal structures of both phases are similar, thus that on cooling from high temperatures the ordered c-particles can coherently & precipitate in the c-matrix. The lattice constants d of the two phases differ. In Ni-base single-crystal

superalloys, one often finds: dc& dc. The associated lattice misfit results in an increase in elastic strain energy, e.g., [5, 6]. This misfit and some of its consequences, e.g., its effect on the shape of c-particles, & on Peach–Ko¨hler forces acting on channel dislocations, on rafting and on the formation of interfacial dislocation networks, have been and are still being discussed in the literature, e.g., [7–15]. The ordered c-& particles represent obstacles to dislocation motion.

They are not completely impenetrable, but it is more difficult for dislocations to move through the ordered c-phase than through the fcc & c-channels. The art of SX design partly relies on making it as difficult as possible for dislocations to cut into the c-phase to opti- &

mize creep strength. Making cutting difficult is associated with increasing antiphase boundary energies (APBs), e.g., [16–20], which result from one of the most prominent elementary mechanisms in crystal plasticity: the pairwise cutting of the c-phase, e.g., & [21–23]. While in the literature there are disagreements as far as specific aspects of this cutting process are concerned, SX researchers from academia and industry believe that it is desirable to design alloys with a high c-volume fraction, a high & c-solvus tem- & perature and a chemical composition, which gives rise to high planar fault energies which affect the physical nature of APBs and stacking faults. The c-&

solvus temperature has been considered as especially important and has been highlighted as a reference temperature in many scientific and technological SX publications, e.g., [24–31].

The present work takes a closer look at the thermodynamic properties of four SXs, ERBO/1 (with Re,a CMSX-4 type alloy) and three ERBO/15 variants(Re-free, with higher levels of Mo, Ti and W). It uses resonant ultrasonic spectroscopy (RUS) and dilatometry to measure elastic stiffnesses and thermal expansion coefficients as a function of temperature. It has recently been shown how these four alloys differ in terms of creep properties [32, 33].