H13 alloy spherical powder is the most widely used and most representative hot work die steel. It has high hardenability and toughness in medium temperature environment, excellent crack resistance, and softening resistance at higher temperature. Ability, low heat treatment deformation rate, medium wear resistance, strong cutting machinability, mainly used for additive manufacturing (3D printing).

Traditional machinery manufacturing is our common technology. What are the differences compared with 3D printing technology? Let's understand the comparison between H13-3D printing technology and traditional machinery manufacturing process.

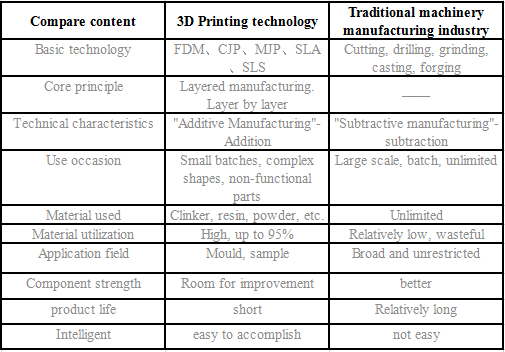

Traditional mechanical manufacturing is based on the combination of cutting, drilling, grinding, casting, forging and other basic subtractive manufacturing processes; the manufacturing of workpieces generally can be completed by combining materials of multiple processes. The 3D printing technology adheres to the core principle of "layered manufacturing, layer by layer", which is a one-piece forming technology. A 3D printer can complete the casting of the entire workpiece. From the perspective of application fields, 3D printing technology is suitable for small batches of non-functional parts with complex shapes, and most of them are used to make molds and prototypes in the automotive, aerospace and other fields. The traditional manufacturing process is suitable for large-scale parts that require mass production, and is widely used in various occasions without restriction. From the analysis of materials and material utilization rate, H13-3D printing technology mainly uses clinker resin and powder, and the material utilization rate is as high as 95%, and there is almost no waste. Traditional machining can use any material, which is much more than H13-3D printing technology. However, traditional "reduced" material manufacturing requires a lot of material waste to the extent that it is not used.

By combining technologies such as industrial digitization and automation, H13-3D printing technology presents three obvious advantages: higher manufacturing freedom, digital work flow, and higher material utilization. The H13-3D printing technology has a short molding cycle and is easier to achieve intelligence, which cannot be achieved by traditional mechanical manufacturing processes. Of course, H13-3D printing technology also has some shortcomings, such as weak mass productivity and component strength needs to be improved. I believe that in the near future, 3D printing technology can have better development.