1. INTRODUCTION

The two of the most common applications of gas turbine in modern industries are Gas Turbo Generator and Gas Turbo Compressor. In a gas turbo generator turbine powerplant there is a generator, to generate electricity the generator needs a prime mover which is the gas turbine. The gas turbine transforms the chemical energy in the fuel (e.g., Natural Gas) into mechanical energy. The mechanical energy generated by the turbine exit shaft is transferred through a gear box to the generators’ shaft. This type of electricity generally has low or medium level of voltage, to convert it into high voltage a step-up transformer is used.

In modern gas turbines to transform the chemical energy of fuel gas into mechanical energy the fuel should be burnt in the combustion chamber of a gas turbine. Air is let in to the gas turbine through an air intake and mixed with a proper amount of natural gas. The ratio of air and gas is determined based on the specific heating value of the gas, quality of air, amount of moisture and altitude from sea level. The ignition system makes the initial sparks providing the required heat. When the fire is stabilized in the combustion chamber the ignition system is shut down. The most critical process in a gas turbine performance is to manage the combustion and generate a proper amount of high-pressure exhaust gas. This exhaust gas is supplied to the turbine which rotates the turbine blades and then rotating the turbine shaft. The air is prone to contamination which can affect the combustion process or even harm the system degrading the overall performance, the screening and filtration are basic initial steps for inlet air. The draft pressure and temperature of the air and the fuel are also monitored with the help of proper instrumentation.

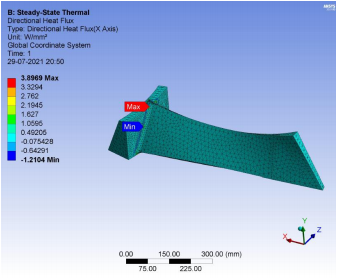

The turbine air compressor an axial compressor comprising of multi-stages of blades mounted radially on the turbine inlet shaft. The two materials for the turbine blade were selected upon extensive research and were found to be the most suitable for high temperature, high frequency and high rotational speed blades. The materials are Inconel 718 and Ti-6Al-4V. The designing of the blade is carried out in Solidworks 2019 and analysis in ANSYS 2019 and 2020.

2. Analysis

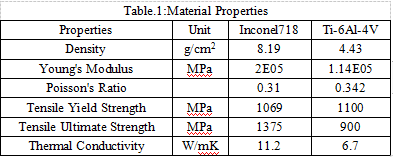

Analysis of the turbine blade is carried out in ANSYS 2019 and 2020. The blade is analyzed at 3500 rpm kept constant throughout the analysis. The elemental step of the analysis procedure is defining the mesh. The method for meshing is tetrahedrons. Later on, the boundary conditions are added. The properties for the materials are defined in the software as mentioned in table-1.

Fig -1: Meshed Model of Turbine Blade

Fig -1: Meshed Model of Turbine Blade

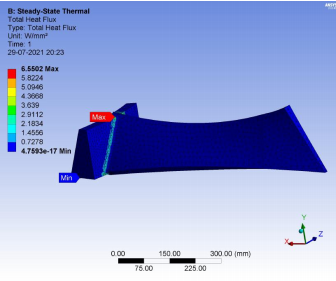

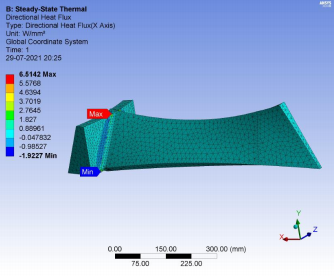

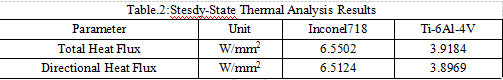

2.1 Steady-State Thermal Analysis

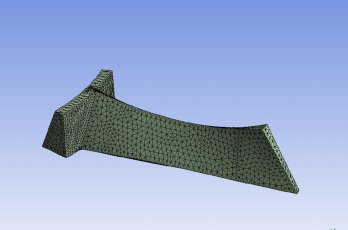

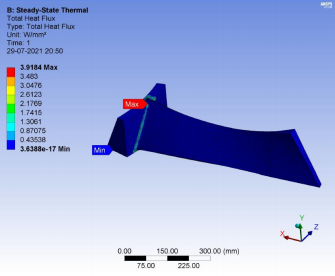

The initial temperature, root temperature, turbine blade temperature is defined as 23℃, 300℃ and 1200℃ respectively for both Inconel 718 and Ti-6Al-4V alloy. The results are in terms of total heat flux and directional heat flux.

Fig -2: Total Heat Flux for Ti-6Al-4V

Fig -2: Total Heat Flux for Ti-6Al-4V

Fig -3: Directional Heat Flux for Ti-6Al-4V

Fig -3: Directional Heat Flux for Ti-6Al-4V

Fig -4: Total Heat Flux for Inconel 718

Fig -4: Total Heat Flux for Inconel 718

Fig -5: Directional Heat Flux for Inconel 718

Fig -5: Directional Heat Flux for Inconel 718

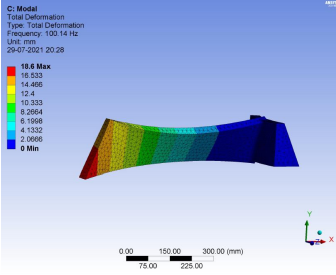

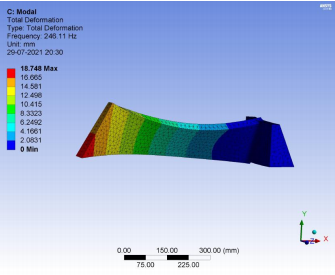

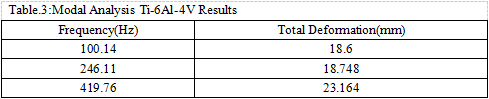

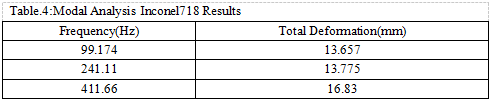

2.2 Modal Analysis

The total deformation from modal analysis for Ti-6Al-4V is established at frequencies 100.14Hz, 246.11Hz, 419.76Hz and for Inconel 718 is carried out at 99.174Hz, 241.11Hz, 411.66HZ.

Fig -6: Total deformation for Ti-6Al-4V at 100.14Hz

Fig -6: Total deformation for Ti-6Al-4V at 100.14Hz

Fig -7: Total deformation for Ti-6Al-4V at 246.11Hz

Fig -7: Total deformation for Ti-6Al-4V at 246.11Hz

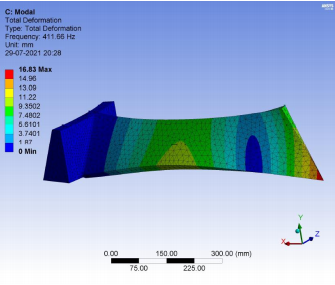

Fig -8: Total deformation for Ti-6Al-4V at 419.76Hz

Fig -8: Total deformation for Ti-6Al-4V at 419.76Hz

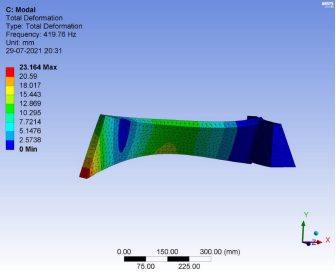

Fig -9: Total deformation for Inconel 718 at 99.174Hz

Fig -9: Total deformation for Inconel 718 at 99.174Hz

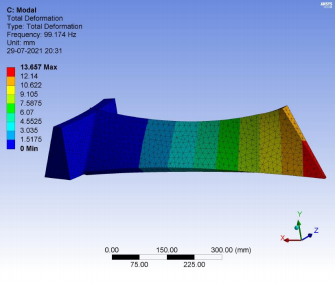

Fig -10: Total deformation for Inconel 718 at 241.11Hz

Fig -10: Total deformation for Inconel 718 at 241.11Hz

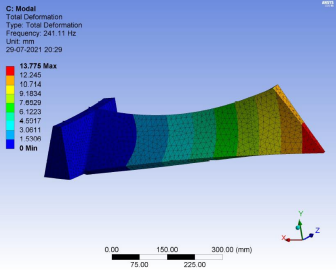

Fig -11: Total deformation for Inconel 718 at 411.66Hz

Fig -11: Total deformation for Inconel 718 at 411.66Hz

3. RESULTS

3.1 Ti-6Al-4V

The results for steady-state thermal analysis show maximum total heat flux to be 3.9184 W/mm2 and maximum directional heat flux to be 3.8969 W/mm2. The total deformation from modal analysis at 100.14Hz, 246.11Hz, 419.76Hz is 18.6mm, 18.748mm, 23.164mm respectively.

3.2 Inconel 718

The results for steady-state thermal analysis show maximum total heat flux to be 6.5502 W/mm2 and maximum directional heat flux to be 6.5124 W/mm2. The total deformation from modal analysis at 99.174Hz, 241.11Hz, 411.66Hz is 13.657mm, 13.775mm, 16.83mm respectively.

4. CONCLUSIONS

It can be concluded from the above results that both materials give considerable results. The total heat flow is about 40% lower than that of Inconel 718 alloy. Therefore, Ti-6Al-4V material is better than Inconel 718. For these two materials, the total deformation of all three modes is increasing. But similar to Ti -6Al-4V, Inconel 718 becomes smaller and smaller at almost the same frequency. For other materials, Inconel 718 is a better choice.