Samples of 150 x 27 x 7 mm3of Nickel alloy 718 alloy were manufactured using a common commercially available Nickel alloy 718 wire for welding applications (1.2 mm diameter). A Precitec CoaxPrinter laser head was used with a continuous laser beam to create an annular spot focused on the substrate, where the wire is coaxially fed into the melt pool, allowing to deposit the alloy layer by layer. Laser power of 2000 W, scanning speed of 1.2 m/min and wire feeding rate of 2 m/min were used for laser and wire metal deposition of the samples. Each deposited layer is in average 1 ±0.2 mm in height. The laser source is a IPG 10 kW Yb3+ - doped fibre solid-state laser with an operating wavelength of 1070 nm. The samples were deposited in an inert gas (Ar) atmosphere along a continuous bidirectional scanning strategy using an ABB IRB 6640-185 robot. The bidirectional scanning strategy consists in alternating building direction between each layer. Samples were cut in the x-z plane, z being the building direction and y the laser scanning direction, and prepared for both electron microscopy and electron back-scattered diffraction (EBSD) analysis by polishing respectively with 3 and 1µmdiamond solution then 0.5µmSilica suspension (OPS).These analysis were performed with 20 kV on a Zeiss Gemini SEM500 equipped with an Oxford Instrument Symme try camera for high resolution maps. EBSD analysis were performed with a 300 nm step for macro mapping, and 200nm step for micro mapping.

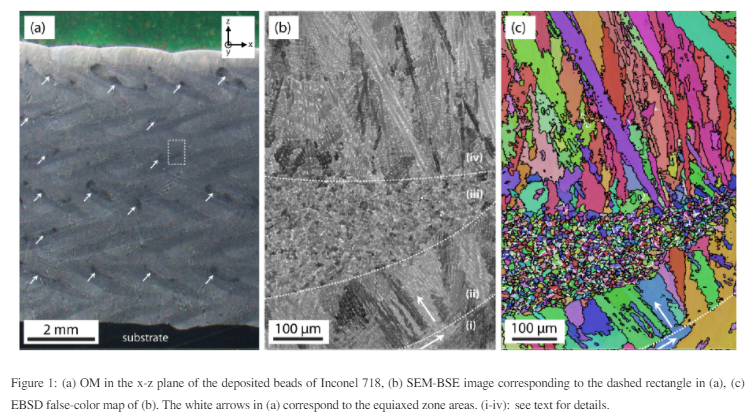

Figure 1(a) shows an optical micrograph (OM) in the x-z plane, y being the laser scanning direction. The macro scopic ”zigzag” grain structure is typical from bidirectional deposition. Some areas, indicated by white arrows in the figure, appears in darker contrast and correspond to the fine equiaxed microstructure areas. In order to confirm that the grains are indeed equiaxed and not rotated columnar dendrites following the thermal gradient in the y-z plane of the molten pool, OM were taken in the y-z plane containing the scanning direction (not shown). The micrographs confirm that the fine grains are equiaxed, and surprisingly we have found that they form a continuous layer in the y direction. One of the equiaxed zones is shown in more details in Figure 1(b) on a SEM-BSE image. The area corresponds to the white dashed rectangle in Figure 1(a). Four distinct zones can be observed: (i) the n−1layer in which growth direction is indicated by an arrow; (ii) columnar growth in the nth layer by epitaxy from layer n−1 where the change of growth direction is indicated with a white arrow; (iii) columnar-to-equiaxed transition leading to a fine equiaxed microstructure; (iv) equiaxed-to-columnar transition in which oriented growth leads to a columnar microstructure. Figure 1(c) is the false-colour EBSD map corresponding to Figure 1(b) where the different transitions are clearly visible. In this figure, identified twin grain boundaries are outlined with white lines whereas random grain boundaries (GB) with a misorientation >10 deg. are shown with black lines: the twin boundaries are only detected in the equiaxed zone. The distributions of the grain size and orientation have been obtained from the EBSD and grain data. Table 1shows the average grain size deduced from EBSD measurements and the relative twin frequency.

For columnar grains, the minimum Feret diameter was chosen to evaluate the grain size since their length can vary significantly depending on the observation plane. The columnar grains are ≈37 µmin width and their length can reach hundreds of micrometers, or even millimeters. The equiaxed zone shows a significant grain refinement with a size <5µm. Moreover, the twin frequency is about 1.3% in the columnar zone, close to the value in a MacKenzie distribution . On the contrary, it is about 13% in the equiaxed zone, close to the value reported by Kutuldu et al.when 200 ppm Ir is added to Au–Cu–Ag alloys in which an ISRO-mediated nucleation mechanism has been demon strated . In order to prove that this nucleation mechanism is similar to that identified in Al–Zn–Cr alloys and Au–Cu–Ag–Ir alloys, multiple-twin orientation relationships between several fcc grains must be identified.